Vacuum Tribology R&D

Focused, responsive, state-of-the-art R&D supporting your development

Get in touchVacuum Tribology Research and Development (R&D)

The application of ‘good tribology’ contributes significantly to the efficiency, reliability and performance of European spacecraft mechanisms. ESTL offers independent, specialist support in this field. Our ESA-funded research is published for the benefit of the space mechanisms community within the ESA Member States.

Tribology Applications Programme (TAP)

On behalf of ESA, ESTL carries out an annually-defined Tribology Application Programme (TAP) of research defined in response to trends and advances in spacecraft mechanisms and within a wider industrial context, for example in the following areas:

- Hybrid lubrication (combined solid/fluid lubricant solutions)

- Improved and lower-cost solid lubricants

- Component-level and actuator level assessment/characterisation

- Improved understanding of present generation fluid lubricants and characterisation of new lubricant chemistries

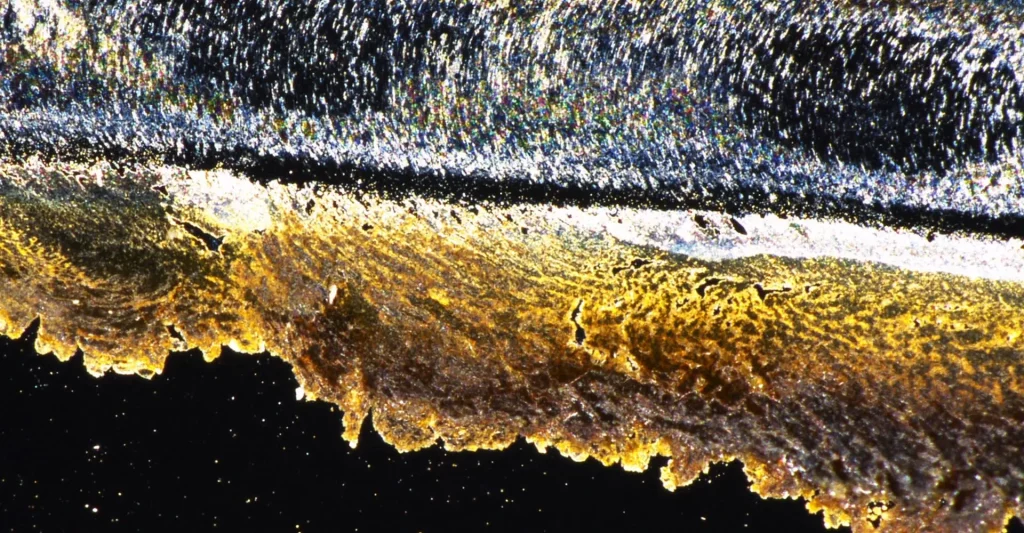

- Quantitative assessments of lubricant condition and inspection techniques

- Assessments related to accelerated life-testing of fluid and solid-lubricated bearing systems

The TAP activities are fully funded by ESA and as such results are disseminated for use by industry through the ESTL Members’ Area of our website.

Commercial R&D

Where additional focused or project/product specific support is required by the client, or for clients working in non-space applications (e.g. terrestrial vacuum applications such as vacuum pumps, precision optical systems, particle accelerators, beam-lines or other vacuum processes) ESTL can provide tailored and entirely confidential R&D on a commercial basis to organisations from around the world as appropriate.

R&D Support Hardware

ESTL has a comprehensive set of specialised vacuum test facilities including:

- Vacuum Pin-in-Disc Tribometers (PoD) – Multiple sliding tribometers for assessment of friction and wear of solid and fluid lubricants under vacuum between -100°C and +200°C or cover gas environments.

- Spiral Orbit Tribometer (SOT) – Specialised rolling tribometer for assessment of lubricant consumption (i.e. life) and friction coefficients operable under vacuum between -50°C and +120°C or under cover gas. The SOT features representative kinematics of an angular contact ball bearing (rolling and pivoting) and can provide data in much shorter timescales than conventional angular contact bearing tests.

- Vacuum Mini-Traction Machine (VMTM) – A unique tribometer for characterisation of fluid or solid lubricants under controlled slide/roll ratios in vacuum between -100°C and +120°C or under cover gas. VMTM can be configured to provide imaging of the lubricated contact.

- Gear test rigs – Fully automated bespoke testing hardware for spur gear component level tests as well as for the evaluation of gearbox unit level performance (for example harmonic drives/spur gears etc.)

- Advanced Bearing Test Rig (ABTR) – Angular contact bearing test facility featuring the capability to assess axial shaft displacement and active monitoring of bearing preload, allowing in-situ film thickness and/or wear or other raceway changes to be inferred.

- Detailed support and inspection hardware.