ESTL – European Space Tribology Laboratory

Explore further, test better.

Innovate with confidence.

Get in touch

Who we are

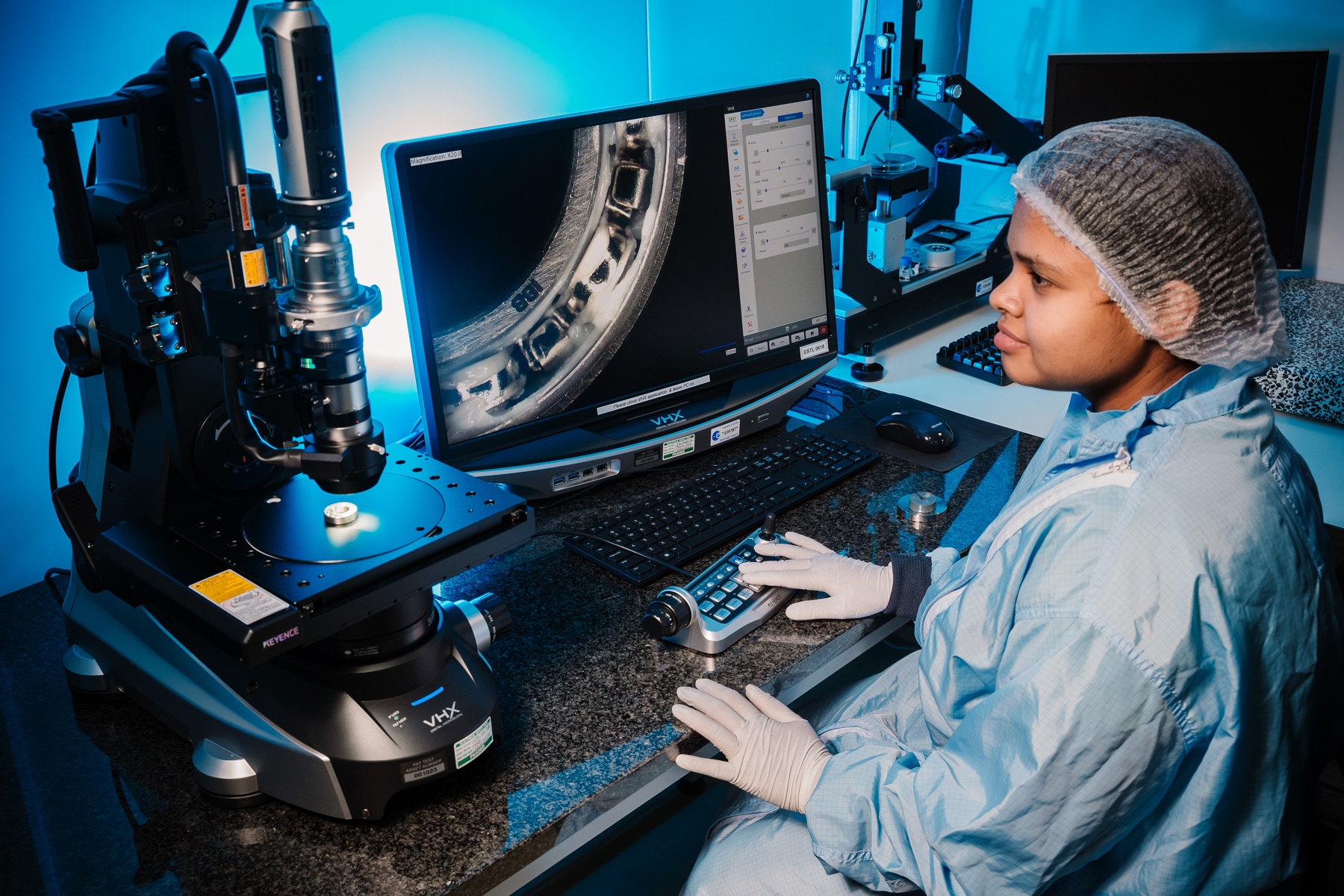

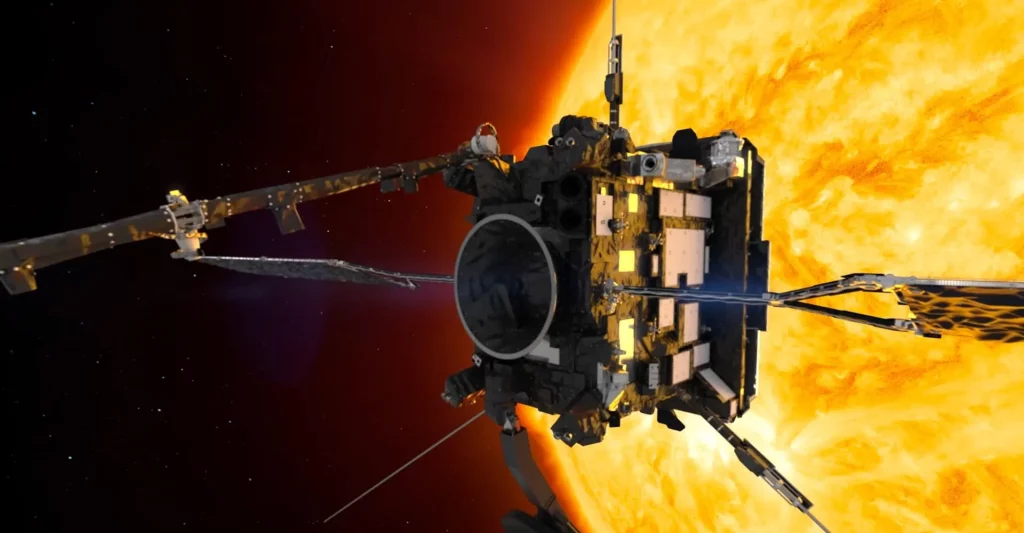

We are the European Space Tribology Laboratory. The European centre of excellence in the science and engineering of friction, lubrication and wear in vacuum environments, including space.

We provide expertise and bespoke lubrication solutions for precision mechanisms operating on the ground, and in space. We help our clients achieve optimal mechanism performance and life, no matter what the vacuum application.

With over 50 years heritage as ESA’s external tribology laboratory, our support helps clients control development risks, maximise the value of test campaigns and meet mechanism performance, life and cost targets.