Ever wondered what’s really happening in a bearing contact? What happens when you run a solid lubricated bearing in air? How a grease lubricant behaves compared to an oil? The Advanced Bearing Test Rig (ABTR) at ESTL is helping us answer those questions.

Tribology is complicated. Various tribometers exist to remove some of this complexity so that lubricant behaviour can be studied in simplified contacts in some detail, but eventually the performance of new/existing lubricants needs to be evaluated in real components. This is where ESTL’s Advanced Bearing Test Rig (ABTR) can help.

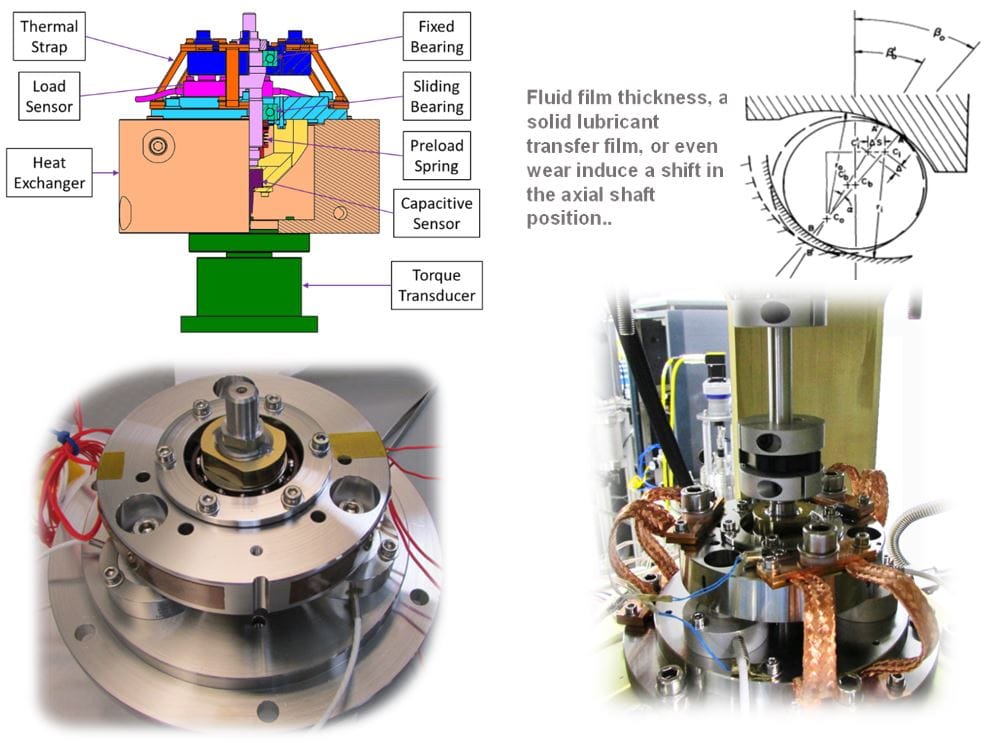

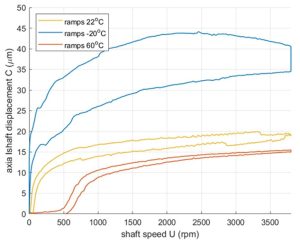

Traditional bearing test rigs might only allow you to measure the bearing torque which is useful but lacks context. Is that high friction due to wear, a lack of lubricant or maybe even too much lubricant? The ABTR allows us to measure preload changes, electrical resistance changes and most importantly the axial shaft displacement which is a measure of the average lubricant film thickness in the bearing contacts. This can be done under vacuum and across different temperatures. Such information allows us to detect which lubrication regime the bearing is operating in, how much of the ball/raceway contact area is metal-to-metal when in boundary lubrication and even the very first onset of wear as the lubricant becomes less effective.

Recent work using our ABTR facilities has included the ongoing validation of a new self-lubricating polymer cage material, a promising replacement material for PGM-HT. This study, presented at the ESMATS 2021 conference, and also available in Europe and Canada online through our Members Area in our Technical Memo (ESA-ESTL-TM-0297 01-) showed a potential improvement in lifetime and performance based on the test results.

For more information on the ABTR and how ESR Technology’s in-situ bearing measurements can benefit your space applications, please contact Research and Development Engineer Adam Wade.