ESTL is excited to announce that ESR Technology has recently become the home of a new mass-spectrometer, the RADIAN ASAP!

ESTL recently presented the exciting work they have been doing with this technology at ESA’s Mechanisms Final Presentation Day, showcasing the fantastic possibilities for considering the health of common space lubricants. This work is ongoing but the results to date show:

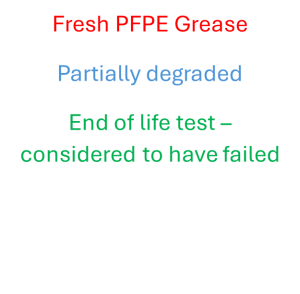

- RADIAN ASAP can be used to assess differences between different levels of tribo-chemical degradation for PFPE lubricants

- Associated software can be used to compare lubricant samples to a health model and categorise its level of degradation

- Very small quantities of lubricant are required for analyses, with sampling not significantly impacting the amount of oil remaining in the contact

In the coming months, ESTL hopes to perfect the technique in relation to the predominant space lubricant chemistries and over time to build a library of their degradation characteristics by sampling lubricants from life-tested components. ESTL hopes to be able to answer questions like “How badly degraded was this lubricant at the end of the mechanism test?” or “How much remaining life could this mechanism have?”.

Though the primary use will be in relation to space lubricants and mechanisms, this is clearly a technology with potential for spin-out into general industrial applications, including:

- Characterising typical fluid lubricants

- Differences before and after thermal or tribological ageing

- The presence of contaminants

- Comparing between lubricants

- Considering the composition of different lubricants, both before and after shearing, to evaluate if there is significant risk to changing lubricant in service

- Assessing different additive packages and confirming core additives are present.

- Considering additive health after a period of operational use.

ESTL believes that the opportunities are extensive. For more information, head over to our website www.esrtechnology.com/estl or for enquires email at info@esrtechnology.com