ESTL has recently concluded an activity into exploring Surface Functionalisation Technologies for their application to Space Mechanisms.

Project Background

Tribological lifetime is frequently the main factor limiting the useful life of spacecraft mechanisms, including on-board instruments and ultimately in some cases the entire spacecraft/mission duration. Frictional losses may drive overall power requirements, and variations in tribological behaviour (instability of cages/ torque noise etc.) can severely limit the performance of mechanisms and ultimately even impact the main goals of a spacecraft through increased micro-vibration levels. Given this, the maximisation of lubricant life and functionality are frequent concerns for the spacecraft mechanism engineer.

This activity consists of a developmental project, performed as a collaboration between ESR technology/ESTL (UK) and Airbus D&S (DE) (plus other partners) into the use of Surface Functionalization (SF) techniques as means to enhance lubricant performance for various spacecraft mechanism applications.

State-of-the-art SF techniques included within this study were wide ranging, including Laser Surface Texturing (LST), Direct Laser Interference Patterning (DLIP), Ion-Etching, Physical Vapour Deposition (PVD), and Electrical Discharge Machining (EDM). Various space mechanism tribo-contact domains, encompassing both fluid- and solid-lubricated applications, were considered, and key areas of potential application were selected. Applications considered include bulk lubricant reservoirs and passive displacement techniques, oleophobic surfaces for fluid retention, directional-oleophilic textures for improved EHL film support within bearing raceways, improved lubricant uptake in cotton phenolic cages, retention of 3rd-body debris particles for longer solid lubricant lifetime in tribo-contacts, and improved substrate clean and adhesive properties through high-energy etching.

Key results

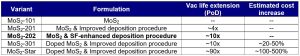

SF-enhanced pulsed ion-etching processes displayed clear success, with this technology being used to extend the tribological lifetime of subsequently deposited PVD MoS2, and displaying compatibility with next-generation self-lubricating composites without compromise of torque during bearing tests.

Given this success of this technology, and its origin as a refinement of the pulsed ion-etch process identified by other development activities at ESTL, MoS2 enhanced in this way is given the designation MoS2-202. A roadmap for further development has been identified, including further assessments at component level (angular contact ball bearings and spur gears), an appropriately scaled demonstration in a representative application (i.e. mechanism level), and QA/productization considerations including cost and availability. The full development roadmap is anticipated to take 18 – 24 months to complete, but MoS2-202 may be considered for development applications earlier than this timescale.

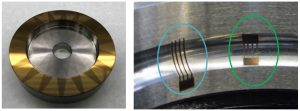

Laser surface texturing for improved fluid film behaviours provided mixed results. At flat sample level the directional-oleophilic behaviours of the textures were observed to encourage lubricant flow, but this could not be conclusively demonstrated at component level due to plastic deformation of the substrate as a result of raised lips to the sides of the textures. Lubricant reservoirs and passive displacement technologies were tentatively successful, but also could not be verified at component level.

Further development activities on LST include reducing the energy input from the laser such that the Heat Affected Zone (HAZ) is reduced significantly, improved planning regarding their locations to prevent them contributing negatively to the tribological performance, and post-texture polishing to remove the abrasive particles.

Contact Details

For more details on MoS2-202, and general applicability of SF-enhanced technologies for space mechanism applications, please contact us!