The 20th World Conference on Non-Destructive Testing, held in Incheon, Korea, featured a significant presentation by Dr Mike Laws from HOIS. The presentation highlighted HOIS’s extensive research over the past 15 years focused on assessing the performance of non-destructive testing (NDT) techniques for identifying and quantifying corrosion under pipe supports (CUPS).

Understanding CUPS

CUPS is a critical issue in asset management, particularly in the oil and gas industry. Pipe supports are essential for maintaining the position of pipes, however they can create crevices that may accelerate corrosion. Movement within these supports can cause fretting, exacerbating the problem. Over time, this can lead to leaks, major ruptures, and even fires, especially as assets age.

Challenges in NDT for CUPS

Several factors complicate the NDT of CUPS:

- Varied Pipe Support Designs: Different types and geometries of pipe supports and pipes, varying in diameter and wall thickness.

- Access Limitations: Supports often cover corrosion-prone areas, making direct access difficult without disassembly.

- Volume of Inspections: Large facilities may have thousands of pipe supports, requiring efficient management.

NDT Techniques and HOIS Trials

HOIS categorised NDT techniques into three groups:

- Fast Screening: Techniques like visual inspections and long-range guided waves offer qualitative assessments to identify areas needing further investigation.

- Enhanced Screening: Methods providing more quantitative assessments, such as guided wave techniques or shear horizontal EMATs, though with a conservative margin of error.

- Quantitative Assessment: Techniques aiming to measure remaining wall thickness with high accuracy, typically used where screening has indicated potential issues.

HOIS’s research included trials on ex-service pipes with real CUPS and specially designed test pipes. Over 250 inspections using more than ten different systems were conducted up to 2018.

Key Findings

The trials yielded valuable insights:

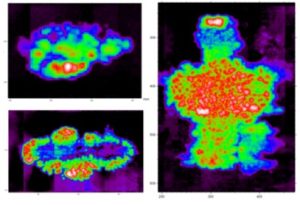

- Tangential Radiography: Effective for small bore pipes but remaining thickness measurements are usually limited to the 6 o’clock position.

- Short-Range Circumferential Guided Waves: Suitable for thinner-walled, larger diameter pipes but quantitative only up to 50% wall loss.

- Ultrasonic Bulk Wave-Based M-Skip: Effective for thicker-walled pipes.

HOIS summarised these findings in a detailed guidance document, updated in 2019. This document, however, is exclusive to HOIS members.

Recent Advances

In 2022, HOIS began investigating three new promising NDT techniques:

- Pitch-Catch Phased Array.

- Multi-Mode Guided Wave.

- Newer Circumferential Guided Wave Systems.

These techniques were tested, showing promising results, particularly for thin-walled pipes, and performed on par with or better than older methods. However, more evidence is needed to confirm their accuracy in measuring remaining ligament thickness.

Conclusion

Effective management of CUPS is crucial in the oil and gas industry due to the complexity and potential risks involved. While screening methods are vital, quantitative sizing often becomes essential. HOIS’s 15-year research program has significantly advanced understanding of NDT capabilities, identifying gaps and potential solutions. Newer technologies show promise in filling these gaps, and ongoing efforts aim to refine their applicability.

HOIS continues to update its guidance document with the latest findings, offering valuable resources to its members. For those interested in the cutting-edge developments in NDT for CUPS, joining HOIS could provide access to these comprehensive insights.

For more information or enquiries, you can head to our website https://esrtechnology.com/hois/ or email us at info@hois.co.uk