Extended Qualification of a Telecom Solar Array Drive Baseplate Assembly for OneSat Missions (Completed November 2022)

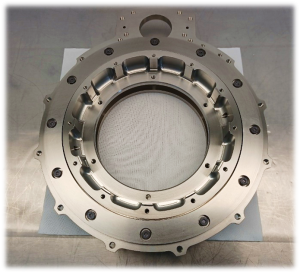

The approach taken for Solar Array Drive Mechanisms (SADM) for the OneSat constellation programme has been to extend the heritage of a proven bearing assembly, reusing an existing design which has been produced by ESR Space over the past 2 decades. As such, revalidation of the SADM bearing lifetime was needed, involving an extended number of rotations, with more severe thermal gradients applied across the bearings.

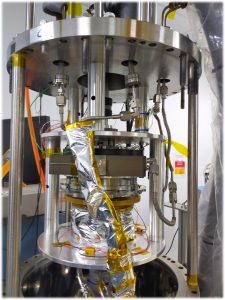

A test plan was developed to extend the mechanism heritage to cover all foreseen cases for the OneSat programme and a specialised test rig was built and commissioned by ESR Space. This provided the ability to apply controlled temperature gradients across the bearings at hot and cold plateaus in vacuum. Two independently controlled heat exchangers were implemented, making use of a radiative coupling to heat or cool the rotating shaft, ensuring not to over-constrain the mechanism.

Airbus UK Solar Array Drive Mechanisms (SADM) have accumulated significant heritage over decades of re-use in communications satellites, proving to be highly reliable mechanisms that utilise lead lubrication, known for its resilience to a wide range of operating temperatures and operation in moist air conditions. Notably, thermal boundary conditions differ significantly in these newer applications on smaller, high-capacity, reconfigurable satellites (satellite image courtesy of Airbus D&S).

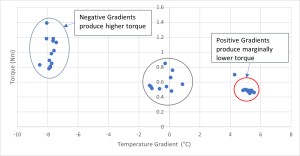

Results of Torque Testing at Controlled Gradient Conditions

Testing of a flight quality SADM baseplate was completed, with temperature gradients and angular positions controlled and recorded throughout the test. Representative stepping sequences were applied in succession. Reacted torque was recorded at all plateaus to gather a complete picture of torque margins over the operating range.

The tested bearing assembly performed nominally with a run-in duration of roughly three times the normal run-in sequence duration. Following testing, the setup was stripped down and bearings extracted to confirm the state of the critical tribological surfaces, in line with ECSS post life-test investigation requirements. Results of testing over temperature, as well as the strip-down went well and met all expectations of the client, Airbus D&S.

(Content approved by Airbus D&S UK – Nov.9, 2023)