The challenge: Our client had identified a recurring issue with con rod bolt failures in an industrial engine, resulting in several catastrophic failures. We were tasked with identifying the root cause, and recommending process changes to alleviate the issue.

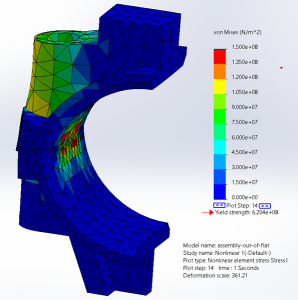

Our solution: Through a range of theoretical and lab-based investigations, we identified the geometry of the joint itself as a key factor in the failures. We build a FE model of the bolted joint to characterise its behaviour under different loads. We were then able to use the parameters we calculated in hand-calculations to quickly narrow down the load cases of interest, before returning to FEA to give a detailed picture of stresses in the bolts, and identify the origin of the failure.