Industrial Testing Services

Reliable testing to characterise component performance, optimise materials and confirm design choices.

Contact us

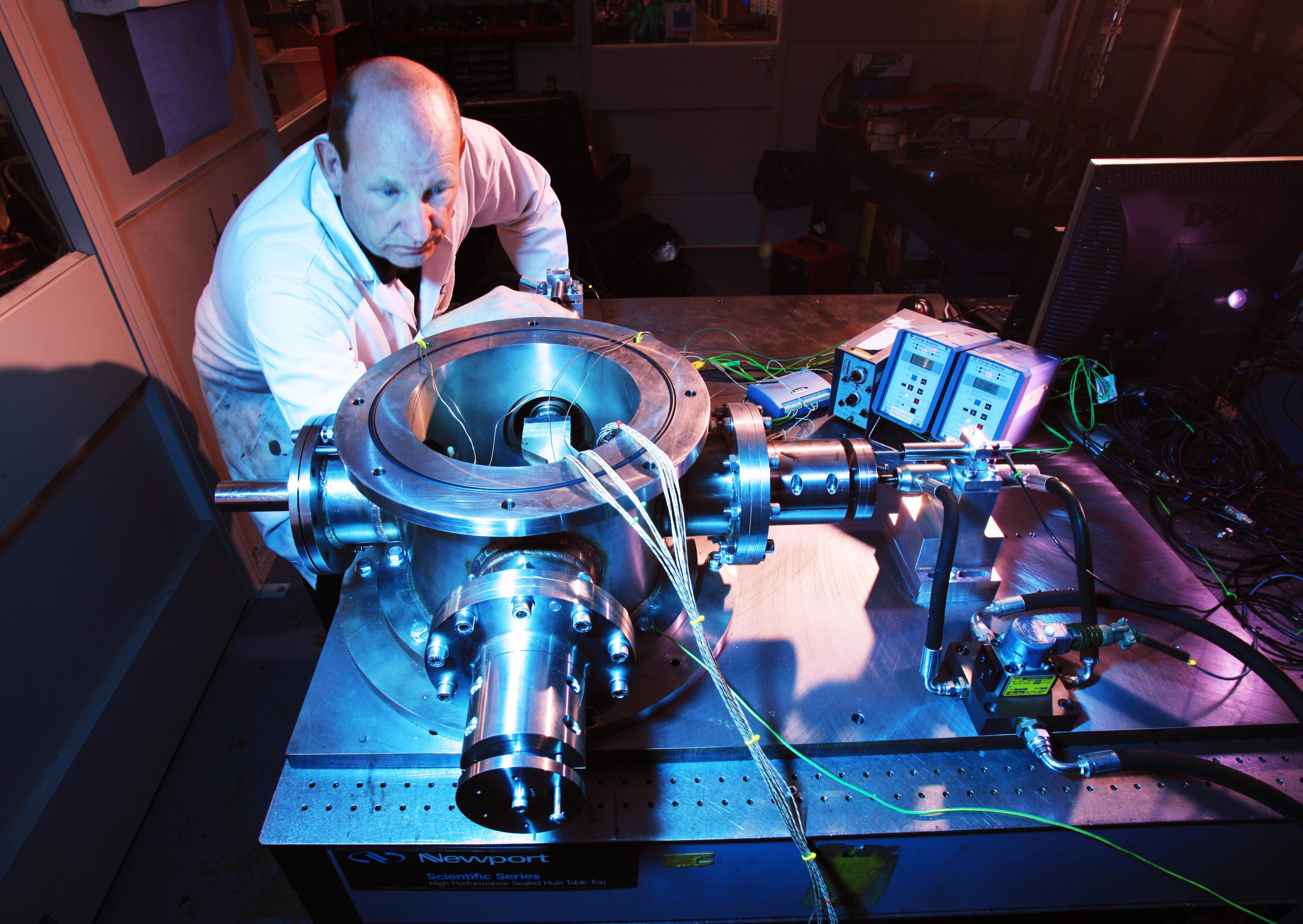

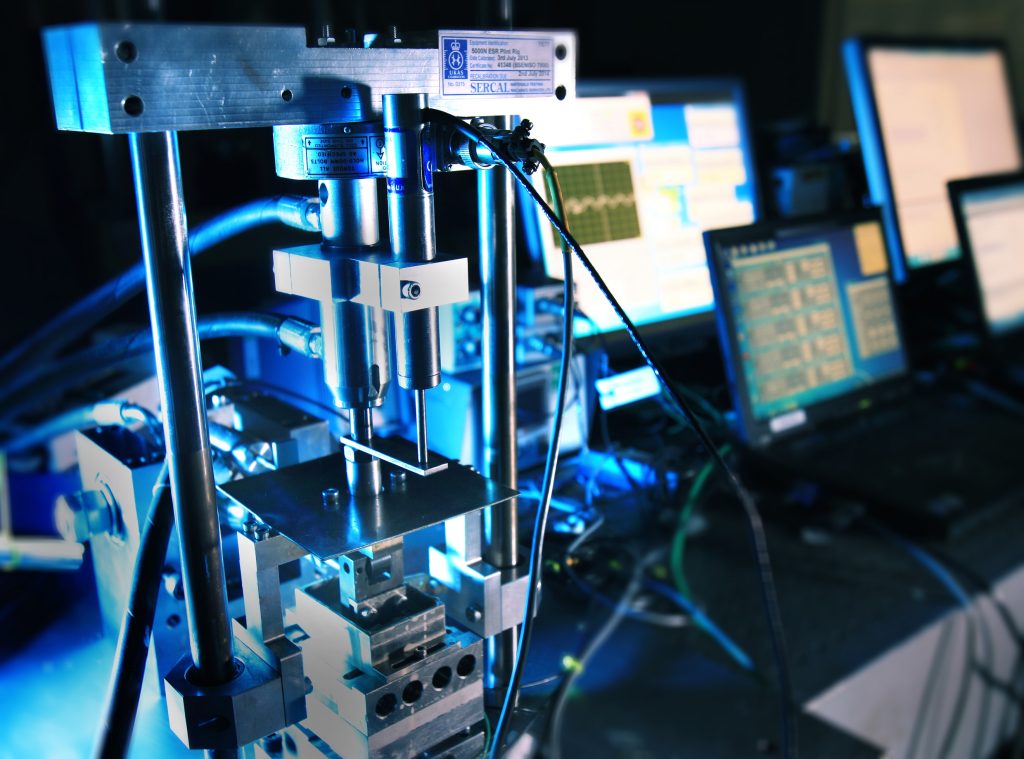

Testing at the National Centre of Tribology

Our NCT laboratory has been involved in tribological testing for many years. Our tests confirm material, surface treatment and lubricant selections for many industrial applications, from downhole drilling operations to nuclear reactors.

Industrial testing

We can test a wide range of contact and loading configurations including under application-representative dynamic loading or service profiles and thermal or environmental conditions to match requirements. Whilst our rigs can be adapted for specific client and application requirements , we also carry out testing in-line with numerous recognised standards. We have a strong background in design and build of custom test rigs where required.

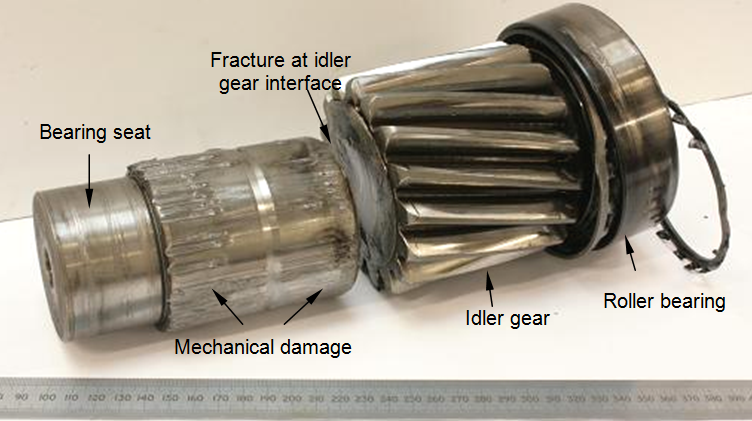

Clients often request evaluation of test pieces taken from production parts, for example to establish or validate current or proposed material treatments. We tailor our test planning to maximise the technical and commercial value obtained from all tests.

We invite you to take advantage of the unique combination of skills and friction-wear testing facilities at NCT to supplement your research and development activities.

Our testing capabilities:

Friction & wear testing:

- We test materials and lubricants for their friction and wear properties under a variety of conditions. This information can be used to select the right materials and lubricants for your application, and to design components and systems that will minimize friction and wear.

Lubricant testing:

- We test lubricants for their tribological performance (e.g. antiwear and extreme pressure tests). This information can be used to select the right lubricant for your application, and to monitor the condition of your lubricants over time.

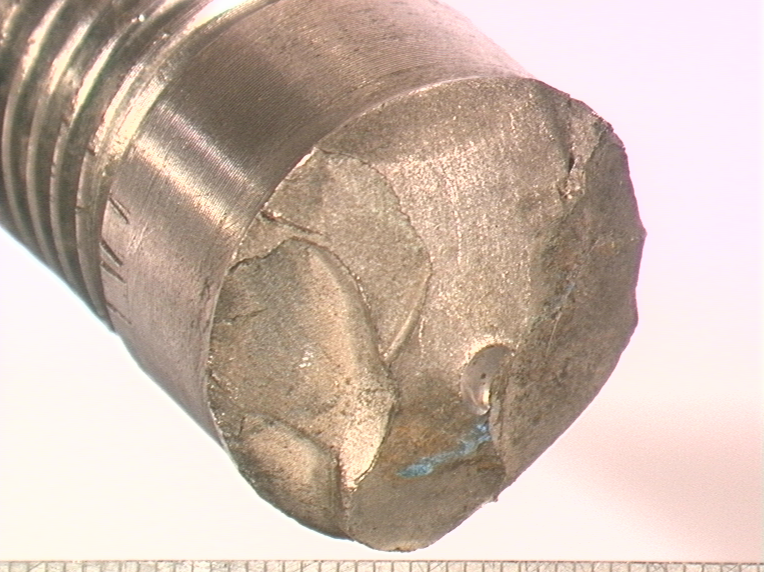

Materials testing:

- We test materials for their mechanical properties, such as hardness, strength, and fatigue resistance. This information can be used to select the right materials for your application, and to design components and systems that will withstand the operating conditions.

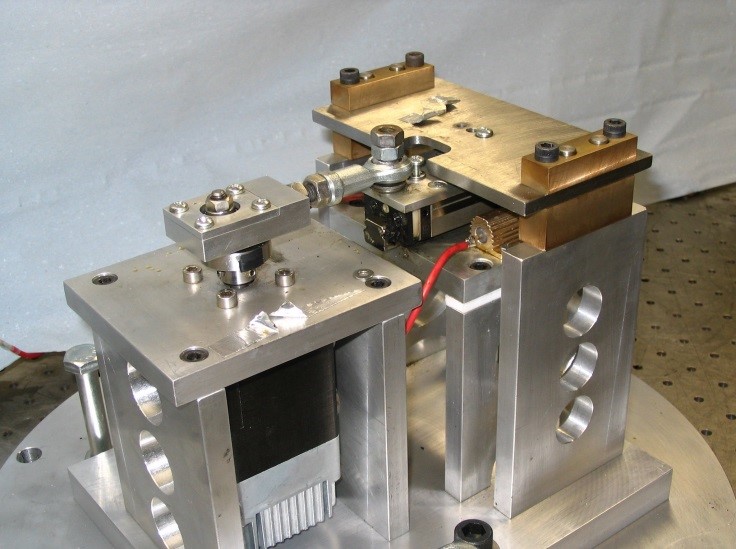

Bespoke rig design and build:

- We design and build custom test rigs to achieve specific test needs, for example, to test a range of materials, lubricants and components under specific loading or thermal conditions. We use digital hydraulic actuation and control systems to ensure precise, repeatable real-world representative testing conditions producing accurate, reliable friction and wear/durability data.

Custom temperature application:

- We can test under controlled thermal conditions, from cryogenic to elevated temperatures. This allows us to test a wide range of materials and lubricants under a variety of operating conditions.