HOIS Highlights 2023-2024

Inspection for SCC Cracking: Uncoated Austenitic Stainless Steel Components

Background

Stress corrosion cracking (SCC) in austenitic stainless steels is difficult to detect and actual sizing of the crack extent is very hard or even impossible with the current techniques due to ultrasonic transparency of tight cracks.

Detection of the surface breaking cracks is challenging when cracks are fine and especially if the surface has been blasted prior to application of dye penetrant testing (PT).

A previous exercise by a HOIS member on the inspection of ex-service austenitic stainless steel samples with stress corrosion cracking, showed that PAUT could detect larger cracks (with a depth of ~50% WT), but the finer, branched cracks were not detected, some of which had a depth of approximately 75% of the wall thickness of the component.

The focus of this work is therefore on the detection and sizing of the finer, branched cracks that can sometimes progress deeper through the material than the larger cracks.

Progress Update

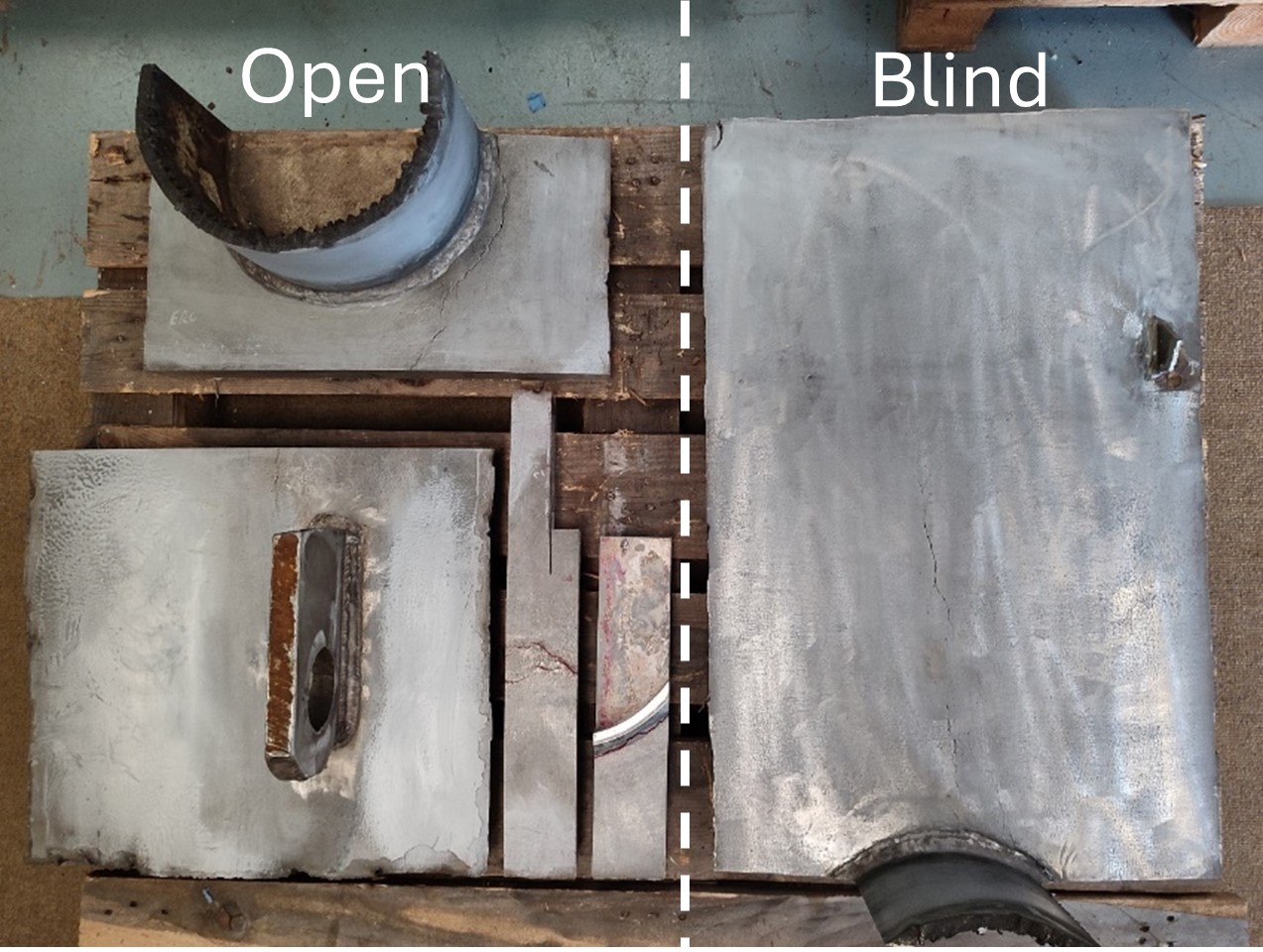

Five ex-service samples containing service-induced stress corrosion cracking were provided by a HOIS member. Four samples were used as open samples to allow trialists to refine their approach and one plate sample was used for the blind assessment.

Eight sectors were marked on the samples the trialists were asked to confirm the minimum remaining wall thickness in each sector. Currently, three trialists have taken part in the blind trial, ETherNDE (DC resistance measurement), Evident (FMC-PCI), and Eddyfi (FMC-TFM & FMC-PCI). AOS-TPAC will also inspect the blind sample using FMC-TFM.

Following completion of the blind trial, the blind sample will be sectioned and the minimum remaining wall thickness mechanically measured to make comparisons with the trialist results.