Pressure vessels and pressure systems represent high hazard items, failure of which may have severe consequences. As such they are required to undergo periodic inspection to ensure continued safe and reliable operation. This generally includes a requirement to inspect the vessel for possible internal degradation which is frequently achieved by means of an internal visual inspection (IVI) requiring man entry coupled with the use of supplementary NDT and surface flaw detection methods.

Increasingly, non-intrusive inspection (NII) is being used to replace IVI for the inspection of the internal surface of the pressure vessel because it reduces the costs and hazards associated with shutting down a vessel (loss of production), isolating it, preparing it for entry and entering it. NII is a process that uses NDT to inspect the vessel while it is on-line, HOIS has developed guidance (HOIS RP 103) to ensure it is applied robustly. However, it is not always a suitable replacement for IVI. For example, it cannot provide information on the integrity of the vessel furniture.

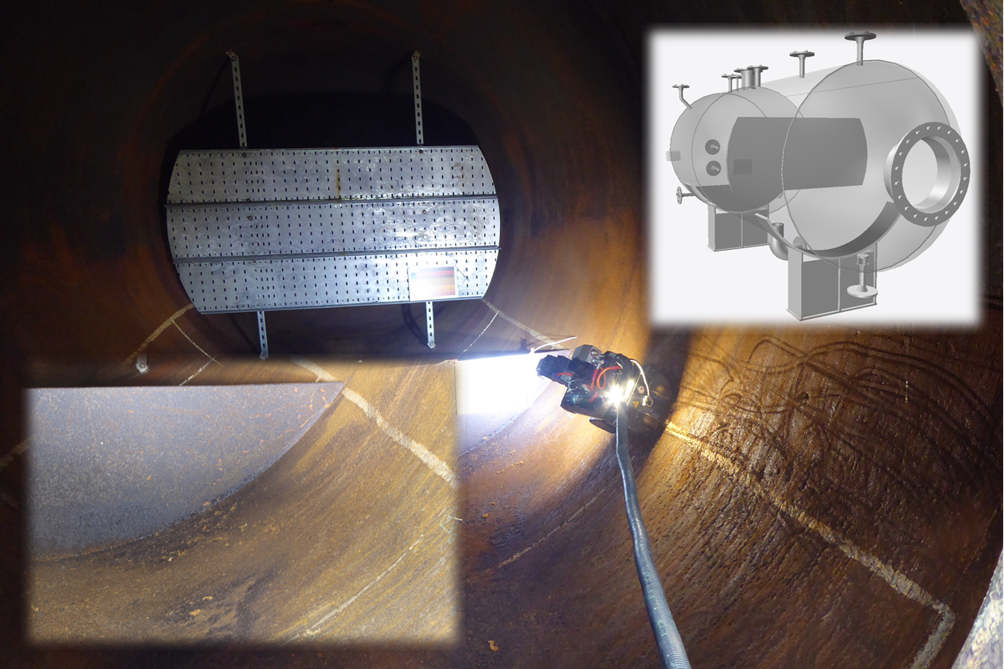

Remote internal inspection (RII) offers an alternative to IVI that can minimise or remove the need for personnel entry and may offer some advantages over IVI and NII. However, the limitations and complexities need to be well understood. HOIS has developed a guidance document which addresses the industry need for a structured approach to RII with the aim of facilitating consistency of application; the document outlines a rigorous approach to ensure that the risks are effectively managed on equipment where the consequence of failure can be severe.

The document has a similar structure to the HOIS RP on NII of pressure vessels and outlines phases of work including: assessment of equipment profile/inspection history and suitability, definition of the work scope, performing the inspection to the scope, and reporting of results through to the final stage of evaluation in which conformance to work scope is reviewed and the RBI can be confirmed/updated.

The process outlined in the guidance document, already issued to HOIS members, was validated in table-top exercises and practical trials on the HOIS ex-service pressure vessel.