Most people have an intuition that putting a notch in a part weakens it. In some circumstances, a notch can actually strengthen a component, although not usually in a desirable way. This phenomenon goes by a number of names, including notch strengthening, notch brittleness, and plastic constraint, which all allude to different aspects of the effect. Notch strengthening is one of the many complicating factors in the study of failures.

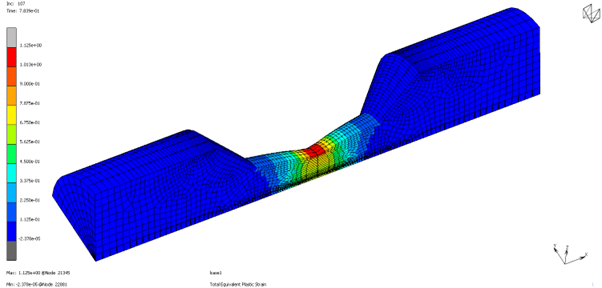

We can’t create or destroy matter, at least not in most engineering contexts, so when something stretches in one direction, it must contract in the other direction. A uniform bar, such as the gauge length of the dogbone specimen above, can happily stretch along its length and thin down as it undergoes plastic deformation. At a certain point, the material can bear no more plastic deformation, and the part ruptures. (Microscopically, this is due to the nucleation and growth of voids, which we modelled using the Gurson Damage Model.)

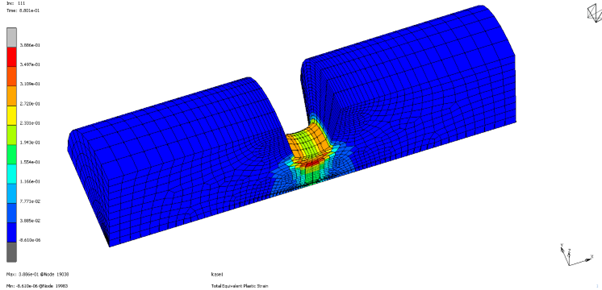

However, consider a dogbone with a much shorter gauge length – something more like a notch. Now, the gauge length is impeded from thinning down by the adjacent thicker portions at the two ends of the dogbone: they are not currently deforming, as the stress is lower there, and hold the gauge length in place. This restriction on deformation is known as plastic constraint.

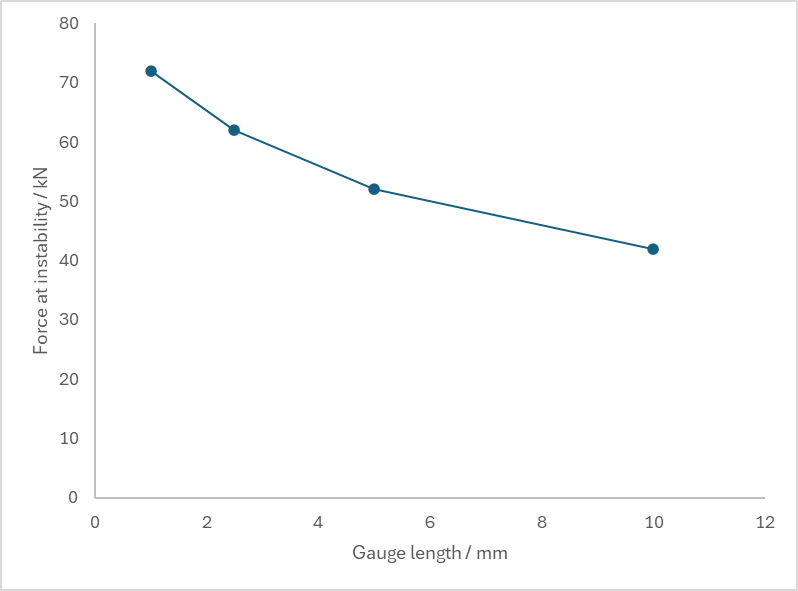

The upshot of this is that the part can only start to deform plastically at a higher stress. In the ideal case, classical plasticity theory tells us that the force required to cause plastic deformation can increase by a factor of three between notched and un-notched parts with the same ruling section. This effect can be seen in the graph below, where we modelled the plastic behaviour of dogbones with different gauge lengths in FEA: as the gauge length becomes shorter and more notch-like, the stress of onset of plastic instability increases, though not to the factor of three predicted by the theory due to the more realistic geometry and stress-strain curves used.

In almost all situations, we design parts to ‘leak before burst’, i.e. they should deform plastically, absorbing energy and giving warning, before failing, instead of failing suddenly, with little absorption of energy and no warning. Designers often neglect the possibility of sudden brittle failure in engineering materials which are normally considered ductile, i.e. they can plastically deform at a stress lower than that which will cause sudden catastrophic failure. However, this is not always a safe assumption: by raising the stress at which plasticity can occur through effects like notch strengthening, as well as incidental factors like temperature, or sudden loading, it is often possible to reach the fast fracture stress without plastic deformation absorbing energy.

Materials which have a brittle failure stress between their uniaxial yield stress and three times the yield stress can be described as ‘notch brittle’, indicating that, while nominally ductile, they can behave in a brittle manner if notched. For instance, with a 0.5 mm flaw size, a mild steel has a critical fracture strength of around 4000 MPa – well in excess of three times the yield stress – so we can be fairly confident it won’t ever fail in a brittle manner (at room temperature). However, a high strength steel might be less tough, with a fracture strength of 2000 MPa. While still more than the yield strength, plastic constraint, could mean that it now fails in a brittle manner if there are notch-like features present.

Notch strengthening is an excellent example of the subtleties of failure analysis, and how failure is not always intuitive: you may have less safety margin that you think, and your failure may be sudden and catastrophic, rather than slow and safe.

ESR Technology can support you in understanding how your part or asset could fail under different conditions, both through laboratory testing, and advanced finite element modelling, coupled with our deep understanding of engineering materials. Reach out to us by emailing info@esrtechnology.com or via our contact page.