HOIS Highlights 2023-2024

Corrosion Mapping of Small Bore Pipework

Background

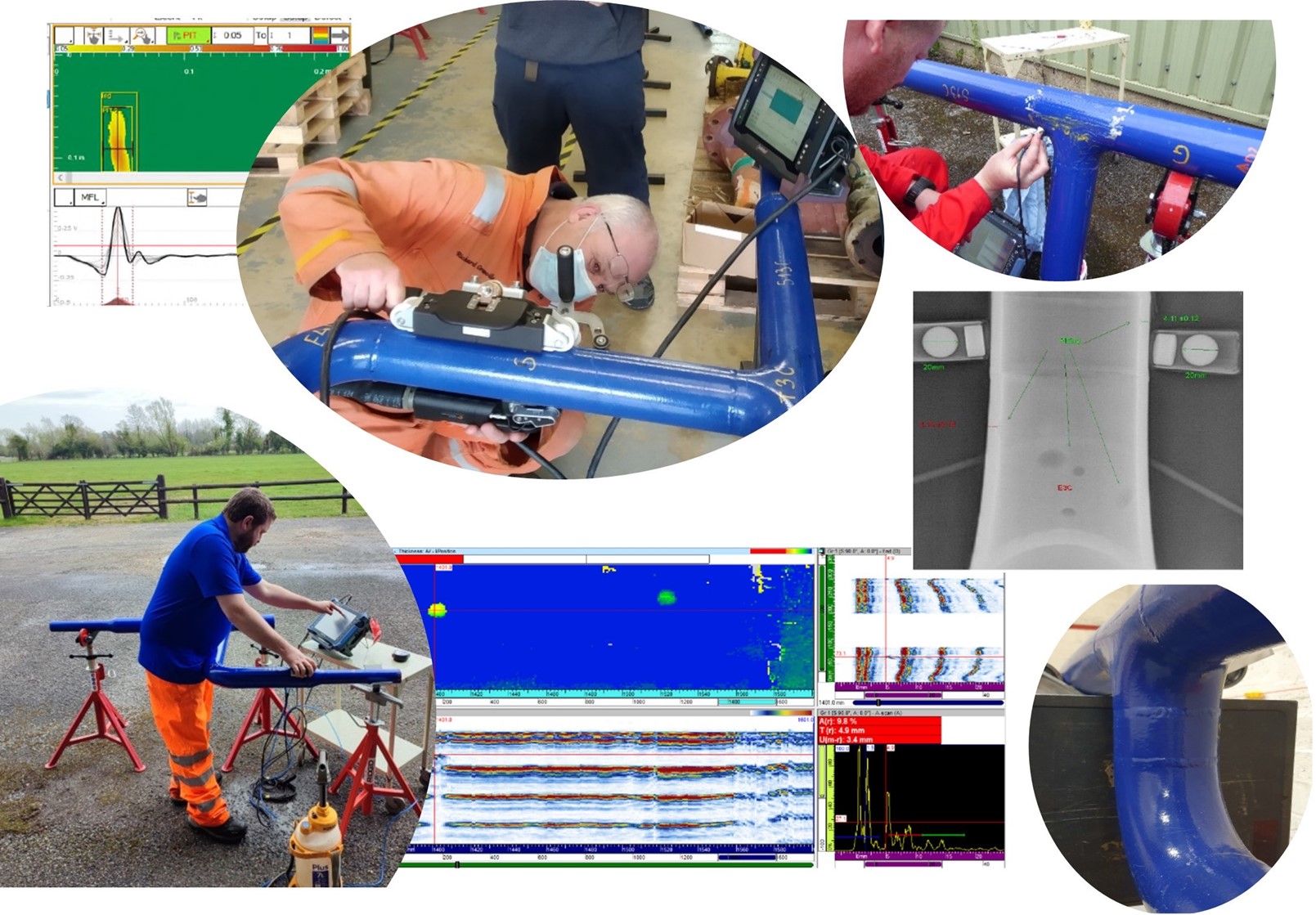

This project considers state of the art corrosion mapping techniques for detection and sizing of internal corrosion on small bore pipework.

The industry has seen continuous improvement in corrosion mapping techniques, (for example, 0° phased array equipment available to scan small bore pipes, elbows and other curved surfaces), but there has been no independent evaluation or validation of these techniques. This project has assembled pipe assemblies on which to perform rigorously controlled blind trials. There is a business benefit to have an understanding of the capabilities/limitations of different techniques in terms of defect size (depth and diameter), morphology, wall thicknesses so as to be able to optimise inspection strategy for a range of components.

The pipe assemblies were comprised of 3″ NB Sch 40 carbon steel fittings (elbows, t-pieces, reducers) and pipe (coated & uncoated), to simulate longer pipework lengths with limited spacing leading to challenging access between pipes. Defects were spark eroded which prevents the requirement of sectioning (and re-welding) of pipework. The defects were carefully designed to explore the effect on POD and sizing of wall loss of depth, diameter and location. The defect morphologies are erosion, small pitting (isolated and in clusters) <10mm in diameter, larger pits <25mm in diameter. Trial participants were not asked to inspect the welds.

The trial programme included participation from Stork working with Novosound, CAN, Oceaneering and Eddyfi.

Progress Update

A detailed trial report has been shared with HOIS members and the results of the trials were used to issue an updated version of the HOIS guidance on this topic.

This project is complete.